Conveyor Belt Scraper Blades

Conveyor Belt Scraper Blades are essential components used in conveyor systems to clean the belt surface by removing residual materials such as dust, debris, or sticky substances. They are typically made from durable materials like polyurethane to ensure long-lasting performance.

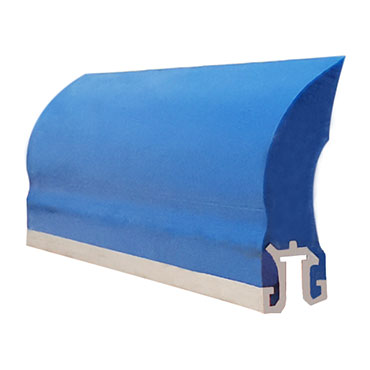

Conveyor Belt Polyurethane Scraper Blades

Characteristics of Urethane Scraper Blade

Polyurethane scraper blades have high abrasion resistance and low coefficient of friction, which enables it to reduce the wear on the conveyor belt; good elasticity, which enables the blade to closely fit the surface of the conveyor belt to ensure efficient cleaning; at the same time, the polyurethane is chemical-resistant, which makes it suitable for various industrial environments and resistant to the erosion of oil, acid, alkali and other chemical substances.Why choose Urethane Scraper Blades?

- 1. Cost reduction: Reduce the replacement frequency of conveyor belt and production downtime caused by equipment failure and avoids the economic loss caused by production delay.

- 2. Improve production efficiency: Reduce production interruptions caused by conveyor belt problems, ensure the continuity of the production line, and ensure the stable operation of the conveyor belt system.

- 3. Enhance product quality: In food, electronics and other industries that require strict product quality, these companies use conveyor belts to transport parts and products during the production process. And keeping the conveyor belt clean helps prevent the products from being contaminated or damaged, ensuring the quality of the products produced.

- 4. Improve the working environment: Reduce the spillage and accumulation of materials in the conveying process, keep the production workshop clean and hygienic, improve the working environment of the employees and reduce the labor intensity.

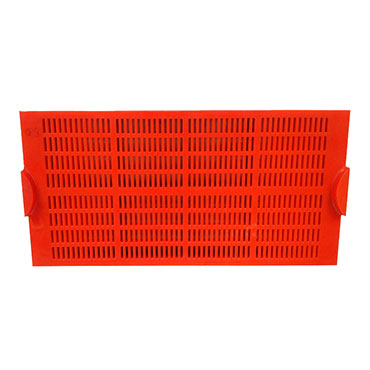

Conveyor Belt Cleaner Replacement Scraper Blade

- Product Specifications

- Gallery

Conveyor belt scraper blade is a replaceable accessory installed on the conveyor belt cleaner, used to remove the residual material on the surface of the conveyor belt. It is usually in close contact with the conveyor belt and can scrape all kinds of materials attached on the conveyor belt in time to keep the conveyor belt clean during the running process of the conveyor belt. It reduces the friction and abrasion between the material and the conveyor belt, prevents the material from accumulating on the conveyor belt, and avoids the problems of conveyor belt running and slipping caused by uneven material. It reduces equipment failure and downtime and ensures the stable operation of the conveyor belt system.

We can design and customize different sizes, shapes and hardnesses of polyurethane scraper blades according to your different conveyor belt widths, belt speeds and the characteristics of the materials to be conveyed in order to meet your diversified application needs and focus on durability, performance, and cost-effectiveness to deliver the best value for our customers.

MDI series prepolymer

| Model | D3560M |

| NCO content / % | 6.0 |

| Viscosity(80℃)/ mpa * s | 1780 |

| D3560M : D3575-C | 100:6.1 |

| Gel time /min | 8-11 |

| Post vulcanization time (100℃)/h | 48 |

| Hardness ( shore A) | 83±3 |

| Tensile strength /MPa | 46 |

| Elongation at break / % | 580 |

| Tear strength (right angle) /(KN/m) | 82 |

| Rebound /% | 38 |

| Density (25℃)/(g/cm) | 1.2 |

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Related Products

Polyurethane Scraper Blades Application Industries

1. Industrial manufacturing industry: such as automobile manufacturing, machining, electronic manufacturing and other enterprises. In the production line, the conveyor belt is used to transport parts and products, the use of conveyor belt scraper blade can ensure the cleanliness of the conveyor belt, to prevent the material residue on the product quality, to ensure the smoothness of the production process.

2. Mining and energy industry: including coal mines, iron ore mines, ores, oil fields, power plants and so on. These industries transport large quantities of materials and highly abrasive, the conveyor belt is easy to wear, scraper blade can effectively clean up the material, reduce the wear and tear of the conveyor belt, to ensure the efficient transportation of energy and ore.

3. Food and Beverage Industry: This industry has very high hygiene requirements, and any material residue on the conveyor belt during the transportation of food raw materials and finished products may lead to product contamination. Conveyor belt scraper blades can promptly remove residual foodstuffs to ensure that the production environment meets hygiene standards.

4. Logistics and Warehousing Industry: Conveyor belts are widely used in logistics centers and warehouses for handling and sorting of goods. Scraper blades can keep the conveyor belt clean, avoiding slipping and damage to the goods during transportation due to conveyor belt problems, and improving the efficiency and accuracy of logistics operations.

5. Chemical industry: Materials conveyed in chemical production are often corrosive or sticky. There are special requirements for the corrosion resistance and cleaning effect of conveyor belt scraper blades. Polyurethane scraper blades can effectively clean the materials and prevent the conveyor belt from being corroded or the materials from sticking to affect the conveying effect.

6. Building materials industry: such as cement factories, glass factories, etc., the conveyor belt needs to transport a large number of powdery, lumpy materials. Polyurethane scraper blades can effectively clean up these materials, prevent them from accumulating and affecting production, and ensure the stable operation of the production line.

Yes, we specialize in customizing polyurethane scraper blades to meet your unique requirements, including specific dimensions, shapes, hardness levels, and industry-specific needs (e.g., food-grade, Light or heavy-duty applications).

Replacement frequency depends on usage intensity and operating conditions. However, polyurethane blades typically last longer than other materials, and regular inspections can help determine when replacement is needed.

Absolutely. Our polyurethane scraper blades are designed to withstand heavy-duty applications, such as mining and cement industries, where high abrasion and tough operating conditions are common.

To determine which type of scraper blade is best suited for your conveying system, there are a number of factors to consider. The following is a detailed analysis:

1. Conveying Material Characteristics

- 1) Material type: Different types of materials have different requirements for scraper blades. For example, for powdery materials, such as flour, cement, etc., the scraper blade needs to be able to effectively clean up small particles, polyurethane material and smooth surface scraper blade is usually more effective, it can closely fit the conveyor belt to reduce the powdery material residue. For granular materials, such as ores, grains, etc., due to its certain hardness and abrasiveness, may require more wear-resistant alloy steel scraper blade to ensure a longer service life. As for viscous materials, such as sauces in food processing and certain colloids in chemical production, scraper blades made of rubber or with special surface treatment can better cope with the flexibility of rubber to adapt to the viscosity of the material and scrape it effectively.

- 2) Material corrosivity: If the material to be conveyed is corrosive, such as acid, alkali and other solutions in the chemical industry, it is necessary to choose corrosion-resistant scraper blade material. For example, stainless steel or after special anti-corrosion treatment of the scraper blade, can be in contact with corrosive materials, to prevent corrosion damage to the blade, to extend its service life.

- 3) Material temperature: high or low temperature environment will affect the performance of the scraper blade. In high-temperature environments, such as steel mills, glass factories conveyor belt, you need to choose high-temperature-resistant materials, such as ceramic-coated alloy steel scraper blade to ensure that at high temperatures can still maintain the shape and hardness, and effectively carry out scraping operations. In low temperature environments, such as conveyor belts in frozen warehouses, the scraper blades need to have good flexibility to prevent them from breaking due to brittleness at low temperatures, and rubber or specially formulated polyurethane scraper blades may be more suitable.

2. Conveyor Belt Characteristics

- 1) Conveyor Belt Material: The material of the conveyor belt determines the friction and abrasion of the scraper blade when it comes into contact with it. For example, in the case of rubber belts, softer rubber or polyurethane squeegee blades will provide a better fit, reduce wear on the belt, and ensure good scraping results. For PVC conveyor belts, it is necessary to consider that the scraper blade material will not cause chemical erosion and can effectively clean the surface material.

- 2) Conveyor belt surface shape: If the surface of the conveyor belt is flat, most types of scraper blades can be applied. However, if the surface of the conveyor belt has patterns, bumps or special textures, it is necessary to choose a scraper blade that can adapt to this shape. For example, a rounded or multi-angle scraper blade will fit better on a conveyor belt with a pattern, ensuring that all parts can be effectively cleaned.

- 3) Conveyor Belt Speed: Conveyor belts running at high speeds require scraper blades that can respond quickly and effectively to scrape away material. When running at high speeds, the stability and wear resistance of the scraper blades are required to be higher. In this case, alloy steel and other rigid and wear-resistant material made of scraper blade is more suitable to prevent deformation or damage to the blade in high-speed operation.

3. Equipment operating environment

- 1) Humidity: In humid environments, such as paper mills, sewage treatment plants conveyor system, scraper blade needs to have moisture-proof, rust-proof performance. Stainless steel or moisture-proof treatment of the scraper blade can prevent rust and damage due to moisture erosion.

- 2) Dust and impurities: If the conveying system is located in a dusty environment, the scraper blade is easily worn by dust particles. In this case, choose a material with good abrasion resistance, such as carbide scraper blades, and make sure that the design of the scraper blades can effectively prevent dust from entering the combined parts of the knife frame and blades to extend their service life.

- 3) Space constraints: Some conveyor systems have limited installation space, which requires the selection of a compact, appropriately sized combination of squeegee blades and knife holders. For example, some small conveying equipment may not be able to accommodate large, complex structure of the scraper blade, you need to choose a smaller but powerful scraper blade products.

4. System Maintenance Requirements

- 1) Replacement frequency: If you want to reduce the frequency of scraper blade replacement and improve the continuity of equipment operation, then choose a good wear resistance, long service life scraper blade, such as carbide or high-performance polyurethane scraper blade is a good choice, although its initial purchase cost may be higher, but in the long term can reduce maintenance costs.

- 2) Cleaning Difficulty: Some scraper blades are more difficult to clean after use, while others are designed to be easy to clean. If the material being conveyed tends to stick to the scraper blade, choosing a material with a smooth, easy-to-clean surface, such as stainless steel or a specially coated scraper blade, can reduce the difficulty and time cost of cleaning.

5. Budget constraints

- 1) Cost considerations: The price of different materials and types of scraper blades varies greatly. Under the premise of meeting the performance requirements of the conveyor system, budgetary considerations need to be taken into account. If you have a limited budget, you may choose a cost-effective rubber or common alloy steel scraper blade; if performance is critical and your budget is sufficient, a high-performance carbide or specially formulated polyurethane scraper blade may be a better choice.

By taking all of these factors into consideration, you can more accurately select the type of scraper blade that is best suited for your conveyor system. Our team can also provide expert guidance to help you select the right blade for your application.

How to Install Conveyor Belt Scraper

1. Preparation before installation

- 1) Confirm the model match: Check carefully whether the model and size of the conveyor belt scraper match with the conveyor belt and related equipment used. Ensure that the length, thickness and other specifications of the scraper are in line with the width of the conveyor belt and the installation requirements of the equipment, and that the material can be adapted to the characteristics of the material to be conveyed.

- 2) Check the integrity of the components: check whether the scraper blade, knife frame, fixed bolts and other components are complete, whether there is damage or deformation. If the parts are found to be defective, they should be replaced or repaired in time.

- 3) Clean the installation parts: Use cleaning tools to thoroughly remove dust, oil and residual materials on the conveyor belt, roller and installation position, to ensure that the installation surface is clean and flat, in order to facilitate the correct installation of the scraper and good fit.

2. Installation steps

- 1) Fix the knife frame: Install the knife frame on the support or frame of the conveyor belt according to the designed position. Use bolts, nuts or other suitable fixing devices to fix the knife frame firmly to ensure that the knife frame is firmly installed and accurately positioned so that it will not be displaced during the conveyor belt operation.

- 2) Attach squeegee blade: Attach the squeegee blade to the knife frame. Depending on the type of squeegee, it may need to be secured with clamps, clips, or other connections. Ensure that the blade is firmly mounted and not loose, and that the blade is in even contact with the conveyor belt surface.

- 3) Adjust the pressure of the blade: According to the running speed of the conveyor belt, the nature and thickness of the conveyed material and other factors, reasonably adjust the pressure of the scraper blade on the conveyor belt. Too little pressure may not be able to effectively scrape off the material, too much pressure will increase the wear of the conveyor belt. Generally through the adjustment of the knife frame on the adjusting device to control the pressure of the blade, the adjustment process can be manually rotate the conveyor belt to observe the contact between the blade and the conveyor belt, in order to achieve the best pressure effect.

- 4) Check the effect of installation: Observe the working condition of the scraper in the case of no-load running of the conveyor belt. Ensure that the scraper can follow the conveyor belt running smoothly, the blade and the conveyor belt surface closely fit, no jumping or scraping uneven phenomenon. If problems are found, stop the machine in time to make adjustments.

How to maintain the conveyor belt scraper

1. Daily inspection

- 1) Regular inspection: In the process of equipment operation, arrange someone to inspect the conveyor belt scraper regularly. Check the wear and tear of the scraper blade and observe whether there are obvious scratches, gaps or thinning on the blade surface. At the same time, check whether the knife frame is loose, whether the fixed bolts are loose or fall off.

- 2) Clean up the debris: each inspection, clean up the scraper and knife frame attached to the material, dust and other debris, to prevent the accumulation of debris affecting the normal work of the scraper. Brushes, compressed air and other tools can be used to clean up.

2. Blade replacement

- 1) Determine the timing of replacement: when the scraper blade wear to a certain extent, can not effectively scrape away the material or excessive wear on the conveyor belt, the blade should be replaced in a timely manner. Generally according to the amount of blade wear, scraping effect and the wear of the conveyor belt to determine whether it needs to be replaced.

- 2) Replace the blade correctly: follow the steps opposite to those of installing the blade, first loosen the fixing device, remove the worn blade, and then install the new blade. During installation, pay attention to the direction and position of the blade, make sure the new blade fits well with the conveyor belt surface, and readjust the blade pressure.

3. Knife frame maintenance

- 1) Check the structure of the knife frame: Regularly check the structural integrity of the knife frame for deformation, cracks and other damage. If damage to the knife frame is found, it should be repaired or replaced in a timely manner to ensure that the knife frame can firmly support the scraper blade.

- 2) Lubricate the movable parts: For the movable parts on the knife frame, such as the screw and nut of the adjusting device, regularly apply the appropriate amount of lubricant to reduce the friction between the parts and ensure the flexible operation of the adjusting device.

4. Regular maintenance

- 1) Comprehensive inspection: Carry out comprehensive inspection and maintenance of the conveyor belt scraper at certain intervals (e.g. monthly or quarterly). In addition to the daily inspection items mentioned above, check the overall coordination of the conveyor belt scraper with the conveyor belt, roller and other equipment to ensure that the entire system is operating normally.

- 2) Record maintenance: Establish a detailed maintenance record to record the time, content, and replacement parts of each inspection and maintenance. Through the analysis of maintenance records, potential problems can be found in a timely manner, and maintenance plans can be reasonably arranged to extend the service life of the conveyor belt scraper.