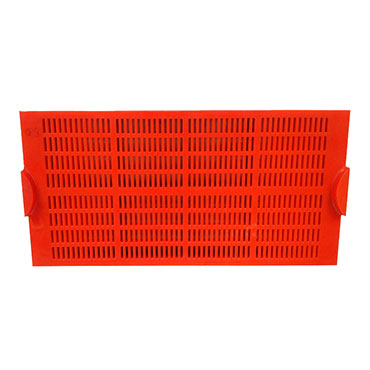

Conveyor Belt Wiper Blades

Urethane wiper blades are replacement parts for primary and secondary belt cleaning systems mounted on conveyor belts to “wipe” materials such as gravel, sand, and stones from the belt. We can custom urethane replacement wiper blades for match your belt cleaner and width of conveyor belts.

Conveyor Belt Wiper for your Belt Cleaning Systems

Characteristics of Our Polyurethane Wiper Blade

- Quality assurance: Our polyurethane wiper blades are made of high abrasion-resistant polyurethane raw materials, strict production technology and quality testing process, and our factory has passed ISO quality system certification.

- Customized service: We provide custom cast urethane wipers blade service according to your conveyor belts specific width and other size requirements.

- Excellent performance: our belt cleaner scraper blades have obvious advantages in terms of cleaning effect, service life, and reduction of conveyor belt wear.

Custom Urethane Wiper for your Belt Cleaning Systems

Secondary lightweight belt sweeper is a 100% polyurethane blade with a simple, lightweight construction for cleaning low belt speeds and small loaded belt systems. It can effectively clean conveyor belts while protecting the cleaner blades from damage and not causing damage to belt joints. It is also more flexible in terms of mounting position than older belts and can be mounted directly under the pulleys.

Secondary heavy duty belt sweeper is a tungsten carbide blade fixed to polyurethane. The compact design allows for installation in tight spaces and the long, narrow profile prevents material buildup. Suitable for high speed, heavy duty belts.

Conveyor Belt Wiper Blade Application scenarios

- Product Specifications

- Gallery

According to the material, conveyor belt wiper blade is divided into rubber, stainless steel, polyurethane conveyor belt wiper blade. According to the function, it is divided into light and heavy conveyor belt wiper blades. According to the application industry, conveyor belt wiper blades are used in food processing industry, mining industry, chemical industry and so on.

We are able to provide custom polyurethane wiper blades in different lengths, widths, thicknesses,hardnesses and polyurethane formula for your conveyor systems.

MDI series prepolymer

| Model | D3560M |

| NCO content / % | 6.0 |

| Viscosity(80℃)/ mpa * s | 1780 |

| D3560M : D3575-C | 100:6.1 |

| Gel time /min | 8-11 |

| Post vulcanization time (100℃)/h | 48 |

| Hardness ( shore A) | 83±3 |

| Tensile strength /MPa | 46 |

| Elongation at break / % | 580 |

| Tear strength (right angle) /(KN/m) | 82 |

| Rebound /% | 38 |

| Density (25℃)/(g/cm) | 1.2 |

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Related Products

Polyurethane sweeper for De-water Cleaning

The flexible polyurethane blade of the de-watering cleaner is like an eraser, which effectively removes backfeed and residual water from the unevenness of the belt surface without damaging the belt. The de-watering sweeper is made of polyurethane knives, which are imported polyurethane material. It is suitable for high moisture content material working condition, and it can deal with the residual moisture of water spraying and collect the moisture effectively.

How do I choose the right size of conveyor belt wiper blade?

There are several key factors to consider when choosing the right size of conveyor belt wiper blade:

- 1. Conveyor belt width: This is the most important factor in determining blade size. The length of the blade should match the width of the conveyor belt, usually the blade length should be slightly larger than the width of the belt, 5 - 10 cm longer is generally recommended. This ensures that the blade can completely cover the width of the conveyor belt during operation, effectively removing moisture, impurities, etc. from the conveyor belt. For example, if the width of the conveyor belt is 80 centimeters, the length of the wiper blade can be 85 – 90CM.

- 2. Installation space: In addition to the width of the conveyor belt itself, it is also necessary to pay attention to the installation space of the wiper. Make sure that there is enough room for the selected blade size in the mounting position. Some equipment may have obstacles or space constraints in the installation area, which requires us to select a blade size that meets the cleaning needs while allowing for a smooth installation.

- 3. Belt Wiper Model: Different models of conveyor belt wipers will have different designs and configurations, and will not have the same suitability for blade size. Some wipers may have specific blade size specifications, so when selecting the blade size, refer to the wiper product manual or consult the supplier to ensure that the selected blade can be perfectly adapted to the wiper.

We mainly produce conveyor belt wiper blades made of polyurethane, which are wear-resistant and durable, and can adapt to a variety of complex working conditions, providing you with a reliable experience.

Absolutely. We specialize in custom polyurethane molding, and we can accurately customize the size of conveyor belt wiper blades according to the specific needs of your equipment to meet your individual requirements.

The service life of the blade is affected by many factors, such as the environment and the operating parameters of the conveyor belt. Generally speaking, under normal working conditions, our polyurethane blades will last longer than rubber blades, and the exact duration can be further communicated according to your actual usage scenario.

The price mainly depends on the product size, material, customization requirements and other factors. After you provide detailed requirements, our sales team will calculate an accurate and reasonable price for you as soon as possible.

Delivery lead time depends on the complexity of the order and production scheduling. Generally, delivery is within [10-15] working days. Customized needs to open the mold, the time may be more than 25 days, the specific delivery period according to your order to further communicate.