Polyurethane Buffer

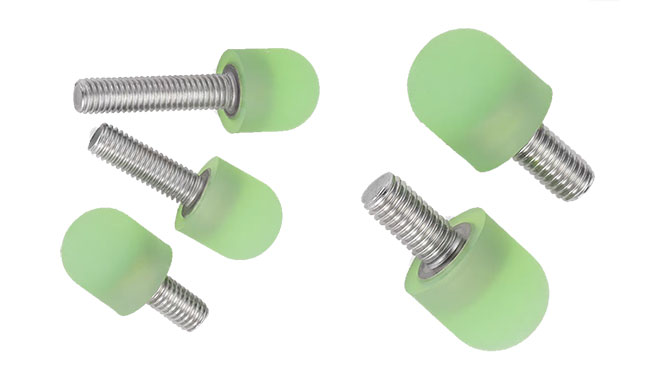

Polyurethane buffer can be a component that absorbs shock or reduces impact and provide cushioning in various applications. Our solid polyurethane buffers are made from polyurethane elastomer materials to provide relatively stable and consistent cushioning for your mechanical equipment.

Polyurethane Elastomer Buffer

Polyurethane Buffer Features

- Good recovery against pressure and wide range of hardness, which can be applied to various occasions requiring buffering.

- Strong impact resistance and still maintains high elasticity at high hardness, so it can be used for buffering of heavy loads.

- Solvent-resistant, corrosion-resistant, and has stable performance for a long time.

- Aging resistance, high wear resistance, long service life.

Advantages of Polyurethane Buffer

- Durability

- Resistance to wear and tear

- Impact resistance

- Chemical resistance

Custom Polyurethane Buffer for Your Equipment

- Product Specifications

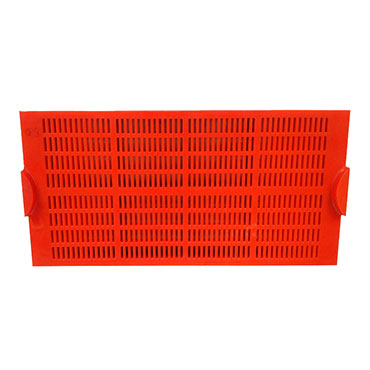

- Gallery

Based on its way of connection, polyurethane buffer could be divided into three series: stud type, platen type, and flange-plate type. For each series, there are 14 to 21 specifications, and each specification corresponds to the buffer of each capacity.

We custom polyurethane buffers in various shapes, hardness, sizes and colors according to your application and installation needs, and can be cast with various metals to make shaped fittings. Meet the requirements of various special occasions.

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Polyether polyols PTMG series prepolymer

| Model | D2135 | D2142 | D3160 |

| NCO content / % | 35±0.1 | 4.2±0.2 | 6.2±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10 | 12.1 | 18 |

| Viscosity(85℃)/ mpa * s | 1200 | 750 | 480 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 85/120 | 80/120 |

| Gel time /min | 11 | 10 | 6 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±2 | 90±1 | 95A±1 (49D±2) |

| 100% constant tensile stress /MPa | 5.4 | 7.5 | 12.8 |

| 300% constant tensile stress /MPa | 9.6 | 14.1 | 36.3 |

| Tensile strength /MPa | 27 | 33 | 48 |

| Elongation at break / % | 550 | 500 | 350 |

| Tear strength (right angle) /(KN/m) | 65 | 78 | 95 |

| Tear strength (pants type) /(KN/m) | 21 | 28 | 33 |

| Rebound /% | 61 | 54 | 47 |

| Density (25℃)/(g/cm) | 1.07 | 1.09 | 1.13 |

MDI series prepolymer

| Model | D3560M |

| NCO content / % | 6.0 |

| Viscosity(80℃)/ mpa * s | 1780 |

| D3560M : D3575-C | 100:6.1 |

| Gel time /min | 8-11 |

| Post vulcanization time (100℃)/h | 48 |

| Hardness ( shore A) | 83±3 |

| Tensile strength /MPa | 46 |

| Elongation at break / % | 580 |

| Tear strength (right angle) /(KN/m) | 82 |

| Rebound /% | 38 |

| Density (25℃)/(g/cm) | 1.2 |

Related Products

Polyurethane Buffer Application

Polyurethane buffers can be used by industrial manufacturers as well as logistics equipment manufacturers to reduce equipment vibration and shock, protect equipment, and improve efficiency.

Urethane buffer are widely used in cranes, elevators, conveyors, automobiles, railroad cars and other areas to protect equipment, improve operational safety and stability, and reduce noise and vibration. It has the advantages of easy installation, long service life and stable performance.

We offer a wide range of specifications for pu buffer, including different sizes, shapes, hardnesses, etc., which can be customized according to your specific needs.

Widely used in machinery, automobile, electronics and other industries, can be used for shock absorption, noise reduction, buffer collision and other occasions.

Under normal use conditions, the service life is long. The specific service life depends on the use of the environment and load conditions and other factors.

According to the specific products and application scenarios, suitable mounting methods can be used, such as bolt fixing, card slot mounting, and so on. When installing, you need to make sure that the installation is firm and the position is accurate.

Prices vary depending on product specifications, performance requirements, quantities and other factors. We will provide a reasonable quotation according to your specific needs.