Polyurethane Bumper

Polyurethane bumpers are protective parts made of polyurethane elastomer material. This material endows them with high strength, good elasticity, and excellent abrasion resistance.

These properties make polyurethane bumpers perfect for withstanding various forces and impacts. Their primary function is twofold. First, they absorb and disperse impact energy. Second, they safeguard the surfaces of machinery or equipment from scratches and abrasions. cast polyurethane bumpers are widely used in automotive and robotics industries.

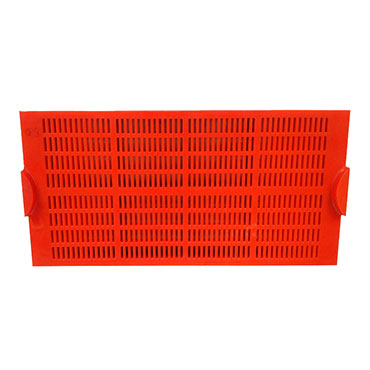

Custom Molded Polyurethane Bumpers

Advantage of Bumper Polyurethane

- Lightweight yet strong

- Duarable

- Cost Effective

- Customizable shapes and Sizes

Feature of Bumper Urethane

- Resilient and Impact Resistant

- Vibration Dampening and Noise Reduction

- Abrasion and wear Resistance

- Corrosion resistance

Urethane Bumpers Manufacturer - Cast Polyurethane Bumpers

- Product Specifications

- Gallery

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Polyether polyols PTMG series prepolymer

| Model | D2135 | D2142 | D3160 |

| NCO content / % | 35±0.1 | 4.2±0.2 | 6.2±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10 | 12.1 | 18 |

| Viscosity(85℃)/ mpa * s | 1200 | 750 | 480 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 85/120 | 80/120 |

| Gel time /min | 11 | 10 | 6 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±2 | 90±1 | 95A±1 (49D±2) |

| 100% constant tensile stress /MPa | 5.4 | 7.5 | 12.8 |

| 300% constant tensile stress /MPa | 9.6 | 14.1 | 36.3 |

| Tensile strength /MPa | 27 | 33 | 48 |

| Elongation at break / % | 550 | 500 | 350 |

| Tear strength (right angle) /(KN/m) | 65 | 78 | 95 |

| Tear strength (pants type) /(KN/m) | 21 | 28 | 33 |

| Rebound /% | 61 | 54 | 47 |

| Density (25℃)/(g/cm) | 1.07 | 1.09 | 1.13 |

MDI series prepolymer

| Model | D3560M |

| NCO content / % | 6.0 |

| Viscosity(80℃)/ mpa * s | 1780 |

| D3560M : D3575-C | 100:6.1 |

| Gel time /min | 8-11 |

| Post vulcanization time (100℃)/h | 48 |

| Hardness ( shore A) | 83±3 |

| Tensile strength /MPa | 46 |

| Elongation at break / % | 580 |

| Tear strength (right angle) /(KN/m) | 82 |

| Rebound /% | 38 |

| Density (25℃)/(g/cm) | 1.2 |

Related Products

Application of Bumper Urethane

- 1.Automotive industry: Commonly used on cars, trucks, and motorcycles. They provide impact resistance, protect against minor collisions, and aid in reducing vehicle damage.

- 2.Industrial equipment: Found on forklifts, cranes, and other heavy machinery. In these applications, urethane bumpers protect the equipment from damage during loading, unloading, and movement within the industrial environment.

- 3.Logistics and warehousing: Used on storage racks and conveyors to prevent damage from moving pallets, forklifts, or other equipment. They help maintain the integrity of the storage and handling systems.

- 4.Electronics and Appliances: Custom molded polyurethane bumpers are employed in electronic devices and appliances as protective buffers. They can prevent damage from accidental drops or impacts.

- 5.Furniture and Cabinet Making: Polyurethane bumpers are used in furniture and cabinet manufacturing to prevent damage, minimize noise, and provide stability when closing or sliding doors and drawers.

- 6.Sports Equipment: Some sports equipment, such as gym machines, treadmills, and weights, use polyurethane bumpers to absorb impact, reduce noise, and enhance safety.

Polyurethane bumpers offer several advantages. They have excellent shock absorption capabilities, which can better protect your vehicles and equipment from impacts. They are also highly resistant to wear and tear, chemical corrosion, and environmental factors. Compared to rubber, polyurethane has better mechanical properties and can maintain its shape and performance over a longer period. And compared to steel, polyurethane is lighter in weight, which can contribute to fuel efficiency in vehicles.

The lead time for custom - made polyurethane bumpers depends on several factors, including the complexity of the design, the quantity required, and our current production schedule. Generally, for relatively simple designs and small quantities, the lead time can be around [2] weeks. For more complex and large - scale projects, it may take [3] weeks. We will provide you with a detailed timeline once we have all the necessary specifications.

Maintenance of our polyurethane bumpers is relatively straightforward. Regularly clean them with a mild detergent and water to remove dirt and debris. Avoid using harsh chemicals or abrasive cleaners as they can damage the surface of the bumper. Periodically check for any signs of wear or damage, and if detected, contact us for repair or replacement advice.

Our polyurethane bumpers are engineered to handle high - speed impacts effectively. The material's unique properties allow it to absorb and disperse the energy from impacts, protecting the vehicle or equipment from damage.

Yes, we are happy to provide samples of our polyurethane bumpers. This allows you to test the quality, fit, and performance of our products before committing to a large - scale order. Please contact our sales team, and we will arrange to send you the samples as soon as possible.