Polyurethane Extrusion

Polyurethane extrusion process allows the manufacture of extruded polyurethane profiles, seals and wear belts with complex geometries and longer lengths. In addition to the round and polyurethane vee belts (used to replace rubber drive belts) that are commonly found on the market. Our outstanding polyurethane extrusion capabilities enable us to produce hollow polyurethane round belts, Non-standard extruded polyurethane sheets, and custom special polyurethane profiles.

The polyurethane extrusion process produces TPU profiles with excellent mechanical properties, flexibility, abrasion and chemical resistance. This provides a reliable and efficient solution for customer-specific applications.

PU Extrusion Capabilities

In order to meet the market demand for urethane drive belt and fast delivery, we keep stock of standard size round drive belts, PU v belts, and can provide custom extruded polyurethane services for non-standard polyurethane products, such as irregular shape extruded profiles, t-cleats, thermoplastic polyurethane sheet, stringer bar capping etc.

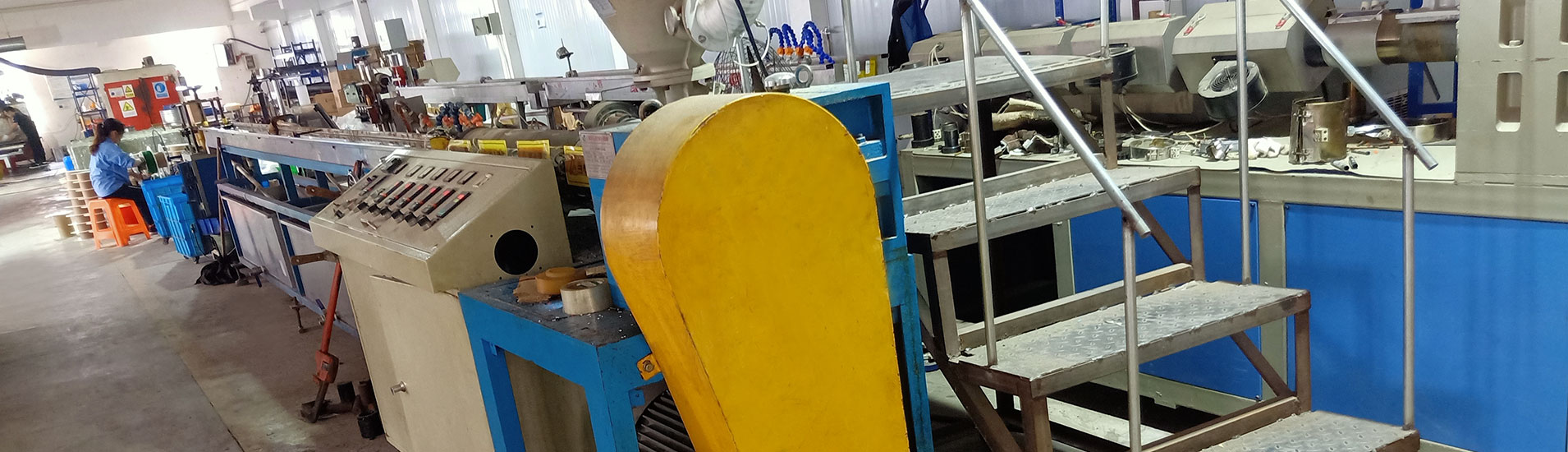

Our different flow rates of polyurethane extrusion equipment and experienced engineers and skilled technical operators. This allows us to meet the unique needs of each customer. From initial design to final production, our team works closely with you to ensure the final product exceeds your expectations.

Advantage of Extruded Polyurethane

Extruded polyurethane products made from thermoplastic polyurethane elastomers (TPU) have a smooth surface finish, which allows for the continuous production of longer polyurethane profiles, increasing efficiency and productivity, and is especially beneficial for mass production.- TPU Raw materials are environmentally friendly and recyclable.

- Good processing performance.

- Good elasticity and excellent wear resistance.

Polyurethane Extrusion Process

Polyurethane extrusion is the process of heating dry polyurethane raw material, extruding and plasticizing it under the action of a screw through an extruder head and die. Extruded polyurethane is used to produce continuous hollow tubes, sheets, Sealing strip, guide strip, cables and profiles made of polyurethane.

Extruded polyurethanes are flexible in design, allowing complex shapes and geometries to be easily realized to meet specific customer needs and application.

Extruded Polyurethane Products Examples

Application scenarios of PU Extrusion

Quality Control of PU Extrusion

The quality of polyurethane extruded products depends on the formulation of the TPU elastomer raw material, the design of the extrusion mold, the temperature and pressure of the extruder, the screw size and other process parameters control.

Our strict process control and raw material quality control have enabled us to pass the ISO9001 system certification. Our company maintains a wide range of cooperative relationships with international first-class material suppliers, such as Wanhua Chemical, INOV, BASF, Bayer, and Covestro, which also enables us to maintain a very strong competitiveness in the development of new materials and the application of new technologies.

PU Extrusion

The hardness range of thermoplastic polyurethane elastomer raw material is 70~95 Shore A, we can develop and custom extruded polyurethane profiles in various shapes and sizes for industries manufacturer or OEM customer.

We can provide one-stop services from molds design and mold manufacturing to product production. We can also provide feasible polyurethane extrusion solutions for customers with special performance requirements such as anti-static, hydrolysis resistance, high transparency and food grade.

Our minimum order quantity depends on the specific product type and production requirements. Generally, it ranges from several hundred meters to several thousand meters.

Usually, the production cycle is 2 to 4 weeks, but the specific time will be affected by factors such as the order quantity and the complexity of the product.

From raw material to the production process of polyurethane extrusion and mold manufacturing, we carry out strict inspections at every step to ensure that the product size meets your drawing requests.

Before confirming the order, we can provide you with samples, but you may need to bear a certain sample cost.

The price is mainly calculated based on factors such as material cost, production process difficulty, and order quantity.

We can extrude various profiles, sealing strips and wear-resistant strips with regular and irregular cross-sectional areas. The gravity of extruded profiles does not exceed 1KG, and the maximum width does not exceed 130mm