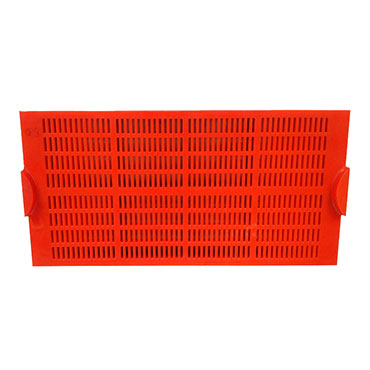

Polyurethane Screen Panels

Our Polyurethane Screen Panels are made from high – performance polyurethane, a material renowned for its exceptional strength, flexibility, and wear resistance. These properties combine to create a screening solution that outperforms traditional materials.

Polyurethane Screen Panels Manufacturers

Characteristics of Polyurethane Screen Panels

- High strength and high toughness

- Precise sieve hole size

- Good Flexibility

- Good chemical stability

Advantages of Polyurethane Screen Panels

- Improve screening efficiency

- Reduced maintenance costs

- Excellent noise and vibration damping function

- Strong adaptability

Custom Cast Polyurethane Screen Panels

- Product Specifications

- Gallery

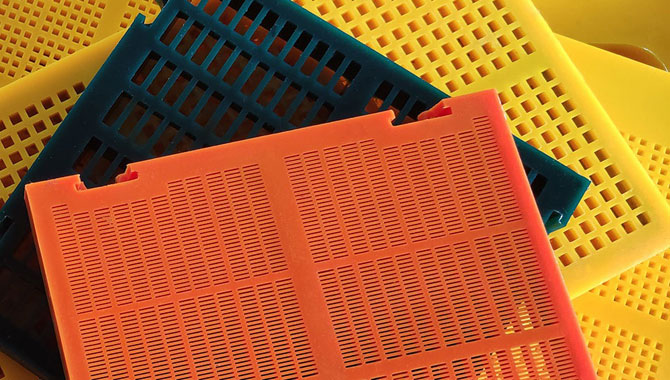

Type of polyurethane screen panels

| Polyurethane Dewatering Screen Plate | Polyurethane relaxation screen | Polyurethane tensioning /flat screens |

| Dewatering screen panel, Pin Type Dewatering Screen Panel, PIPO Screen Panel, Wave Dewatering Screen Panel, WS85 Screen Panel, Dewatering Screen Panel, | Polyurethane relaxation screen, Round hole polyurethane relaxation screen, Flip Flow Screen, | Polyurethane relaxation screen with load bearing blind plate, Polyurethane flat screen with large holes, Polyurethane flat screens with impact beams, Polyurethane flat screen with small square holes, Polyurethane tensioning screen, Polyurethane tensioning screen with anti-clogging design, |

Features of Urethane Screen Panels

- High abrasion resistance: polyurethane material itself has excellent abrasion resistance, in the case of long-term friction and impact of materials, the wear rate is much slower than the traditional metal sieve plate, and it can maintain a longer period of stable screening effect.

- Good elasticity: with high elasticity, it can produce small elastic deformation in the screening process, which helps the material to pass through the sieve holes quickly, reduces the occurrence of sieve holes clogging, and improves the screening efficiency.

- Strong impact resistance: can withstand large impact without damage, even when dealing with large, hard materials, but also to maintain structural integrity, to ensure that the normal screening work.

- Low noise: Compared with metal sieve plate, polyurethane sieve plate can effectively absorb vibration and sound when the material is impacted, reduce the noise generated in the screening process and improve the working environment.

Specifications of polyurethane screen panels

Hole shapes and sizes: The holes are available in round, square, rectangular and trapezoidal shapes.| Dia. of round screen holes (mm) | 0.075 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.5 | 0.6 | 0.7 | 0.86 | 1 | 1.18 | 1.4 | 2 | 4 |

| number of items | 200 | 140 | 100 | 70 | 60 | 50 | 35 | 30 | 25 | 20 | 18 | 16 | 14 | 10 | 5 |

Why choose the screen made of polyurethane?

1. polyurethane dewatering sieve plate has excellent wear resistance, service life is far more than the traditional rubber sieve plate and metal sieve plate. 2. polyurethane tailings dewatering screen plate is acid and alkali resistant, corrosion resistant, can be used in a variety of working conditions. 3. polyurethane dewatering sieve plate has high precision of sieve seam, which can maximize the classification of materials with different particle size. 4. polyurethane dewatering sieve plate has low friction coefficient, the sieve plate does not stick to the material, and the sieve plate is not easy to block the holes. 5. polyurethane dewatering screen plate itself has elasticity, large handling capacity, full dewatering, high efficiency. 6. polyurethane dewatering screen plate is easy to install and convenient to replace. 7. polyurethane dewatering screen plate low noise, reduce noise pollution. 8. Our special double hardness MDI polyurethane screen plate adopts imported three-component MDI polyurethane with different hardness. The upper soft and lower hardness design makes the surface of polyurethane screen plate high resilience, effectively reduce the rate of plugging holes, improve the processing capacity, and wear-resistant effect is better, the use of time is more durable.

Related Products

Polyurethane Screen Panels Application Scenarios

- Mining -In the mining industry, our Polyurethane Screen Panels play a crucial role in ore screening processes. our panels have increased screening efficiency by 20-50% while reducing maintenance costs by 30-70%. Their reliability and long - lasting performance have made them an essential part of the mining operation.

- Construction Materials Industry- For the building materials industry, our Polyurethane Screen Panels are instrumental in ensuring the quality of aggregates and cement products. By precisely separating materials of different sizes, our panels help produce consistent - quality building materials that meet the highest industry standards

- Environmental Protection Industry- In environmental protection projects such as solid waste treatment and sewage treatment, our Polyurethane Screen Panels are used to separate impurities and recover valuable materials. Their efficient screening capabilities contribute to a more sustainable and resource - efficient waste management process.

Our polyurethane screen panels are made of high-quality materials and advanced technology, with excellent abrasion resistance and fatigue resistance, which can maintain good performance in high-load, long-time mining screening operations and significantly extend the service life.

Polyurethane screen panels have good elasticity, in the screening process, the screen panels will produce small elastic deformation, so that the material is not easy to attach and clog the screen holes, can effectively maintain the screening efficiency.

We have a wide range of standard sizes of polyurethane screen panels to choose from. At the same time, we specialize in custom polyurethane products, which can be completely personalized according to the specific requirements of your equipment.

After receiving your demand, our professional technical team will understand the parameters and working requirements of your equipment in detail, and ensure that the polyurethane screen panels are perfectly adapted to your equipment through precise design and strict production process.

- Polyurethane Dewatering Screen Installation Methods: Polyurethane dewatering screen has different installation methods according to the requirements of the screen machine, which are mainly divided into: peg type, bolt type, rail seat type.

- Nail dewatering screen installation method: Peg dewatering screen is commonly used in 305*30 specifications. The screen has four semi-circular mounting holes and legs, when installing, first put the polyurethane dewatering screen plate on the support beam of the vibrating screen machine. A complete rising nail mounting hole will be formed between the screen plate and the adjacent screen plate, and then the rising nail will be nailed in the mounting hole, and the direction of the screen seam needs to be paid attention to when installing, and the screen plate will be installed accurately. Dewatering screen commonly used rising nails have nylon rising nails and polyurethane rising nails, customers can buy their own according to need.

- Installation method of bolt type dewatering screen: Bolt type dewatering sieve has various sizes, there are semi-circular countersunk mounting holes and the most complete countersunk mounting holes, put the screen plate on the support beam of the sieve machine in an orderly manner, and pay attention to the position of the mounting holes of the sieve plate and the mounting holes on the support beam, fix the screen plate with bolts on the support beam, and this kind of installation method is relatively simple. The bolts generally use M12, M14, M16 bolts, which are relatively common and easy to purchase.

- Installation method of rail mounted dewatering screen: The rail seat type dewatering screen plate needs to be used with the corresponding rail seat, due to the different design of each vibrating screen machine factory, the rail seat is also different, but the installation method is the same, firstly, fix the rail seat on the support beam of the vibrating screen machine, then align the mounting groove on the back of the dewatering screen plate with the raised part of the rail seat, knock the screen plate into it, so that the rail seat will be embedded in the groove of the screen plate, that is, the installation is completed.