Polyurethane Spray Nozzles

Polyurethane spray nozzles are made of high-performance polyurethane material with excellent abrasion and chemical resistance and good flexibility. Polyurethane nozzles for screen irrigation systems offer a range of benefits, including durability, precise water distribution, water conservation, enhanced crop health, and cost-efficiency.

Polyurethane Spray Nozzles for Screen Irrigation Systems

Features of Polyurethane Nozzles for Screen Irrigation

- Wear Resistant

- Durability

- Chemical Resistance

- Standard 3/4" BSPM Couplings

Advantages of Urethane Spary Nozzles

- 1. Long service life of polyurethane nozzles reduces the cost of replacement parts.

- 2. Easy Installation and Compatibility with Screen Irrigation Systems.

- 3. Precision irrigation and better uniformity.

Custom Urethane Nozzles Manufacturer

- Product Specifications

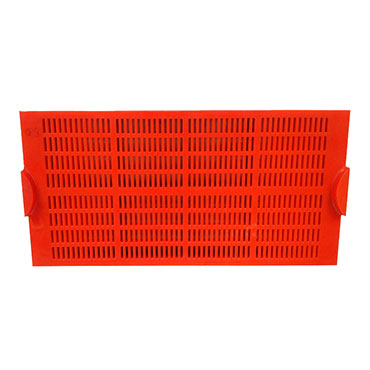

- Gallery

Polyurethane spray Nozzles sizes

- White: 3mm PD3 Spray Nozzle 3/4" BSP

- Green: 5mm PD5 Spray Nozzle 3/4" BSP

- Blue: 7mm PD7 Spray Nozzle 3/4" BSP

- Yellow: 9mm PD9 Spray Nozzle 3/4" BSP

- Red: 11mm PD11 Spray Nozzle 3/4" BSP

- Brown: 13mm PD13 Spray Nozzle 3/4" BSP

- Black: 16mm PD16 Spray Nozzle 3/4" BSP

Date Sheets of Urethane Spray Nozzles

| Nozzle No.5(hole diameter 5mm) | ||||

| Height above screening surface, mm | Pressure, Atm | Spray width, mm | Water consumption ,m3/hour | Water consumption ,l/min |

| 100 | up to 2.0 | 220 | 1.3 | 21 |

| 2.0-5.5 | 250 | 2.0 | 33 | |

| 200 | up to 2.0 | 330 | 1.3 | 21 |

| 2.0-5.5 | 600 | 2.0 | 33 | |

| 300 | up to 2.0 | 420 | 1.3 | 21 |

| 2.0-5.5 | 700 | 2.0 | 33 | |

| 400 | up to 2.0 | 550 | 1.3 | 21 |

| 2.0-5.5 | 900 | 2.0 | 33 | |

| Nozzle No.7(hole diameter 7mm) | ||||

| Height above screening surface, mm | Pressure, Atm | Spray width, mm | Water consumption ,m3/hour | Water consumption ,l/min |

| 100 | up to 2.0 | 250 | 2.2 | 36 |

| 2.0-5.5 | 270 | 2.8 | 46 | |

| 200 | up to 2.0 | 320 | 2.2 | 36 |

| 2.0-5.5 | 600 | 2.8 | 46 | |

| 300 | up to 2.0 | 620 | 2.2 | 36 |

| 2.0-5.5 | 800 | 2.8 | 46 | |

| 400 | up to 2.0 | 650 | 2.2 | 36 |

| 2.0-5.5 | 900 | 2.8 | 46 | |

| Nozzle No.9(hole diameter 9mm) | ||||

| Height above screening surface, mm | Pressure, Atm | Spray width, mm | Water consumption ,m3/hour | Water consumption ,l/min |

| 100 | up to 2.0 | 300 | 3.4 | 56 |

| 2.0-5.5 | 320 | 3.9 | 65 | |

| 200 | up to 2.0 | 900 | 3.4 | 56 |

| 2.0-5.5 | 1100 | 3.9 | 65 | |

| 300 | up to 2.0 | 1100 | 3.4 | 56 |

| 2.0-5.5 | 1400 | 3.9 | 65 | |

| 400 | up to 2.0 | 1300 | 3.4 | 56 |

| 2.0-5.5 | 1500 | 3.9 | 65 | |

| Nozzle No.11(hole diameter 11mm) | ||||

| Height above screening surface, mm | Pressure, Atm | Spray width, mm | Water consumption ,m3/hour | Water consumption ,l/min |

| 100 | up to 2.0 | 330 | 4.0 | 67 |

| 2.0-5.5 | 360 | 4.4 | 73 | |

| 200 | up to 2.0 | 900 | 4.0 | 67 |

| 2.0-5.5 | 1000 | 4.4 | 73 | |

| 300 | up to 2.0 | 1200 | 4.0 | 67 |

| 2.0-5.5 | 1300 | 4.4 | 73 | |

| 400 | up to 2.0 | 1400 | 4.0 | 67 |

| 2.0-5.5 | 1500 | 4.4 | 73 | |

Screening Media Nozzle

Screening Media Nozzle

Related Products

Polyurethane Spray Nozzles Application

Polyurethane Spray Nozzles are specifically used in dewatering screens and high frequency screens, The spraying systems can provide a suitable concentration for screening and separation, PU flood nozzles are widely used in quarry, mining, aggregate and mineral processing applications.

Our nozzles are made of high-quality polyurethane material with excellent weather and abrasion resistance, which can work stably in long-term outdoor environments, greatly reducing the frequency of replacement and lowering your cost of use.

Yes, our polyurethane spray nozzles have good versatility and can be adapted to a variety of crop screen irrigation systems, and the spray pattern and flow rate can be adjusted according to different needs to meet the irrigation requirements of various types of crops.

Yes, it can. Our nozzles are specially designed and material optimized to have high strength and wear resistance, which can withstand the impact of materials in mining production and guarantee the stable operation of screen irrigation systems.

The installation process is simple and convenient, and no special tools are required. Designed to meet common industry standards and adapted to most screen irrigation systems, the nozzles can be easily installed, saving you time and labor costs.

Our polyurethane spray nozzles have excellent chemical resistance and can be used in a wide range of chemical environments involved in environmental treatments without corrosion affecting performance, ensuring stable operation of screen irrigation systems.