Polyurethane Wheels with Bearings

Polyurethane wheels with bearings have a precise power transmission function, which can effectively transfer power from the drive shaft to the wheel to ensure that the wheel can be accurately walked in a straight line and steering control in the process of operation, to realize the normal drive and operation of the equipment. They are widely used in applications that require continuous power output, such as conveyor belt systems, or in automated equipment and instruments that require very high operating precision.

Custom Urethane wheels with Bearings

Our Custom Polyurethane Wheels with Bearings Services Include

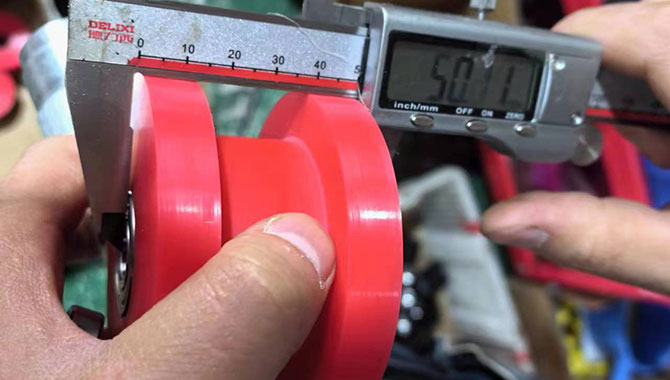

- Size customization: wheel diameter, wheel width, axle diameter, etc.

- Hardness customization: 55A- 80D Shore hardness range, you can choose the right hardness according to different application scenarios.

- Color customization: Provide a variety of color choices to meet the individual needs of customers.

- Bearing customization: Choose the right type of bearing according to the requirements of load, speed and precision.

- Surface Finishing: Surface finishes such as sanding and knurling are available to improve the friction and durability of the wheels.

Characteristics of Urethane Wheels with Bearings

The polyurethane material we use has high wear resistance, good elasticity and vibration damping, excellent tear strength and excellent chemical stability. These properties enable the wheels to operate stably under a wide range of complex working conditions and extend their service life.

Classified by Polyurethane Bearings Wheels Characteristics

- Product Specifications

- Gallery

Advantages of Urethane Wheels with Bearings

1. Durability and Economy: Bearing-covered polyurethane wheels have excellent abrasion resistance, tear resistance and anti-aging properties, which reduces the replacement costs and downtime for maintenance that customers need to carry out due to frequent damage to the wheels. In the long run, this saves the customer a great deal of money in equipment maintenance and operating costs.

2. Comfort and safety: The elasticity of polyurethane can effectively cushion the vibration and impact during operation, reducing the impact of the equipment on the operator and the surrounding environment. On equipment that requires personnel to operate or be in close proximity, such as medical trolleys and office chairs, this comfort enhances the user experience. At the same time, good braking performance and stable operation ensure the safety of the equipment during use and reduce the risk of accidents.

3. Environmental adaptability: Polyurethane materials can be formulated and adjusted according to different application environments, so that they have chemical corrosion resistance, high and low temperature resistance, anti-static and other characteristics. Bearing covered polyurethane wheels are able to work normally in a variety of harsh environments, such as chemical workshops, cold storage, electronic clean rooms, etc., which expands the scope of application of the product and provides customers with a wider range of choices to meet the needs of use in different environment.

Related Products

What is polyurethane wheel with bearings application scenario?

1. Industrial field

- 1) Manufacturing production line: Polyurethane wheels with bearings are used as moving parts for material handling trucks, AGVs (Automated Guided Vehicles) and robots in production lines such as automobile manufacturing, electronic equipment manufacturing, etc. They can accurately control the running direction to ensure the efficient and stable operation of the production line. They can precisely control the running direction to ensure that the materials are accurately transported to the designated position, ensuring the efficient and stable operation of the production line. For example, on automobile production lines, material handling vehicles rely on such wheels to transport parts quickly and smoothly.

- 2) Warehousing and logistics: Forklifts, forklifts, stackers, pallet trucks and other equipment in logistics warehouses use these wheels extensively. The wear-resistant performance and good load-bearing capacity of polyurethane wheels adapt to frequent cargo handling and long-time operation. In large-scale e-commerce warehouses, forklifts have to carry a large amount of goods every day, and polyurethane wheels can withstand heavy loads with little wear and tear, extending the service life of the equipment.

- 3) Mining and construction machinery: In mining and construction, such as loaders, bulldozers and other mechanical equipment, the steering wheel and driving wheel part of the use of polyurethane wheels with bearings. Their high elasticity and impact resistance can adapt to harsh road conditions and high load operations, reduce equipment vibration, and improve operator comfort and equipment stability.

2. Medical Industry

- 1) Medical equipment: Various medical trolleys, such as surgical instrument trolleys, medicine distribution trolleys, examination equipment trolleys, etc. are equipped with polyurethane wheels with bearings. These wheels have good quiet performance to avoid excessive noise interference with patients in the hospital environment; at the same time, the smooth rolling performance of the wheels ensures that the medical equipment can be easily moved under different ground conditions, which is convenient for healthcare personnel to operate.

- 2) Rehabilitation equipment: For rehabilitation equipment such as wheelchairs and walkers, the combination of polyurethane wheels and bearings provides flexible steering and stable support. Its good elasticity can reduce the bumps suffered by the patient during the moving process, improving the experience and safety of using rehabilitation equipment.

3. Office and commercial field

- 1) Office furniture: office chairs, file cabinets mobile wheels are mostly used in this product. It not only can easily support the weight of the human body, but also has good steering flexibility, so that office workers can move freely in the office area and improve work efficiency. And some of the silent design of the wheel, will not produce noise when moving to affect the office environment.

- 2) Commercial display equipment: shopping carts in supermarkets, moving wheels for display racks in shopping malls, etc., need to have durable and smooth characteristics. Polyurethane wheels with bearings can meet the needs of frequent use and long-time rolling, while their appearance can be designed to blend with the commercial environment and enhance the overall aesthetics.

4. Transportation

- 1) Public Transportation: Certain auxiliary wheels or bogie components of some urban rail vehicles may be designed with a combination of polyurethane and bearings. This combination helps to reduce vibration and noise during vehicle operation, improving passenger comfort, while also enhancing the durability of vehicle components.

- 2) Specialty Vehicles: Specialty vehicles, such as baggage tractors and ferries at airports, for example, require frequent starting, stopping and steering in complex ground conditions. Polyurethane wheels with bearings ensure stable operation and improve operational efficiency thanks to their good overall performance.

Our polyurethane wheels with bearings are available in various models, and the load capacity varies from model to model, from tens of kilograms to several tons. You can provide the specific use scenario and demand, our technical team will recommend the right product with suitable load capacity for you.

Our lead time depends on the order quantity and customization requirements, usually 2-4 weeks. We can provide expedited service for customers with urgent needs.

We support small quantity customization, the minimum order quantity can be negotiated according to customers' requirements.

The price mainly depends on the wheel size, material, customization requirements and order quantity. You can provide us with specific product specifications and order quantity, our sales team will provide you with a detailed quotation in the shortest time.

The bearings we choose are from famous brands with reliable quality. During the production process, we strictly follow the quality management system to test each bearing to ensure that it meets the high standard quality requirements.