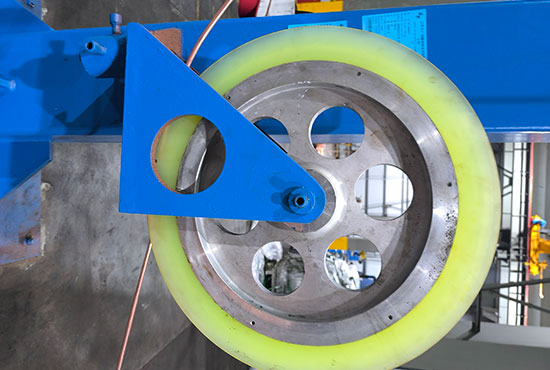

PU Rollers for Steel Industry

PU rollers are used in the steel industry in almost all finishing production lines of strip coils.Polyurethane products have high resilience, high abrasion resistance, low coefficient of friction, and good chemical resistance, which gives them a longer service life than many other materials, reduces the frequency of roll replacement, and meets the high load requirements of continuous production line operation.

In the steel industry, the main finishing lines that use PU rolls are cold rolling lines, galvanizing lines, color coating lines, and leveling and shearing lines.

Polyurethane rollers are used in cold rolling, leveling and other finishing processes to ensure the flatness of the steel plate; in the rolling process, to control the precision of the rolling thickness of the steel plate; in galvanizing, color coating and other production lines, to make the coating of the steel plate uniform, smooth, reduce scratches, and improve the aesthetics of the steel plate. And it plays the role of auxiliary transportation and accurate positioning.

The types of PU rollers can be divided into high hardness (with high strength, high wear-resistant characteristics) tension rolls, steering rollers, guiding rollers, pinch rollers; moderate hardness (with acid and alkali resistance, hydrolysis resistance, wear-resistant, and high processing accuracy) of the squeezing rollers and measuring rollers; low hardness coated rollers (hardness range of 45-60 shore A, machinability, resistance to organic solvents with good performance).

Urethane Products Application

Polyurethane coil saddles pads (steel coil pad) have a key role in steel coil storage and transportation. They are placed beneath the coils. This placement provides support and protects the coils from damage during storage and handling.

High hardness polyurethane tension rollers, steering rollers, and guiding rollers are remarkable. Their high strength and wear-resistant characteristics enable them to meet the high load requirements of metallurgical sheet production lines' continuous operation.

Urethane Rollers Application Areas in Steel

Urethane drying rollers offer excellent resistance to acid, alkali, and hydrolysis. Thus, they prevent the cleaning liquid from the acid and alkali washing section from entering the next process. PU measuring rollers, on the other hand, stand out for their wear resistance and high machining precision. This makes them perfect for meeting the measuring station's specific requirements regarding roller shape and size.

Polyurethane coated rollers, with a hardness of 45 - 60 Shore A, are highly useful. During the coating process, they maintain good elasticity and abrasion resistance. As a result, they prolong the rolls' service life and reduce production costs. They are widely used in cold rolled and hot rolled steel sheet production for anti-corrosion coating and marking, as well as in galvanized and color coated steel sheets.

Advantage of using PU Rollersin the Steel Industry

PU rollers' elasticity brings significant benefits. They can absorb the vibration and impact during equipment operation. This absorption reduces damage to other equipment parts, extends the equipment's service life, and cuts down on equipment maintenance costs.

In the iron and steel industry, as high value-added steel products become more prominent, PU rollers' application in steel manufacturing and processing will expand. Besides rollers, polyurethane is also used in unwinders, winders, and other related transmission accessories. These play important roles, such as protecting steel coils, facilitating loading and unloading, and stabilizing transmission.

PULISEN is located in Liyang, Jiangsu Province, China, covering over 3,000 square meters. We can produce high-quality and durable urethane products according to your design drawing.

If you have any inquiries about custom urethane rollers for the steel manufacturing production line, please contact us.

Explore other Industries Service

Send Inquiry