Urethane Products for Submarine Cable Protection Pipe System

The offshore wind power industry is experiencing rapid growth as a clean and sustainable energy source. Central to the successful operation of offshore wind farms is the protection of power cables. Submarine cable protection pipe systems play a crucial role in safeguarding the integrity of underwater cables, which are essential for various industries such as telecommunications, power transmission, and offshore exploration. Urethane products have emerged as a valuable choice for components within these protection pipe systems due to their unique properties.

Polyurethane elastomers have high tensile strength and tear resistance. This enables them to withstand the mechanical forces exerted on cables in the marine environment. Their resistance to abrasion ensures that the cable jacket remains intact, thus protecting the internal conductive elements.

In addition, polyurethanes are extremely resistant to seawater, oils and a wide range of chemicals, which prevents corrosion and degradation of the cable’s protective elements and prolongs the service life of the cable.

Polyurethane Elastomer Components in Cable Protection Systems

Cable Jackets-Polyurethane elastomer cable jackets provide a tough outer layer of protection. They shield the cable from physical damage, such as cuts and scrapes, and also act as a barrier against moisture and chemicals. The flexibility of the elastomer jackets allows the cables to bend and move with the natural motion of the sea floor without cracking.

Sealing Components- polyurethane elastomer are made gaskets, seals, and connectors are used to prevent water ingress into the cable system. These components create a tight seal at cable joints and terminations, ensuring that the internal components of the cable remain dry and protected from the marine environment.

Armoring Support- In some cases, polyurethane elastomers are used to support and reinforce cable armoring. They enhance the mechanical strength of the armoring, protecting the cable from external forces and improving its overall durability.

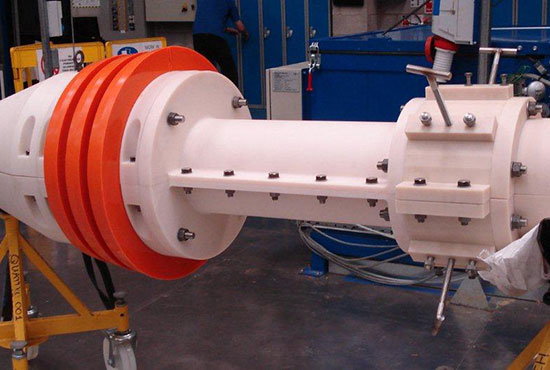

Polyurethane Products Examples in Submarine Cable Protection Pipe System

Polyurethane Cable Bend Restrictors-urethane cable bend restrictors possess high hardness, good toughness, fatigue resistance, and high tearing and impact strength. Their main function? To prevent excessive bending that could damage submarine flexible pipes and cables. By supporting these lines, they ensure no bending or fatigue failures occur under various working conditions, thus extending the service life.

Polyurethane Bend Stiffeners-urethane bend stiffeners are usually tapered with a cylindrical hole. They support flexible pipes, umbilicals, and cables. These stiffeners are often attached to upper or subsea connections.

Polyurethane Riser Clamps-urethane riser clamps replace steel pipe clamps. They are highly impact - resistant, lightweight, and easy to assemble. In conventional drilled water traps, they connect the auxiliary line to the main body. This prevents the riser from bending during operation.

Polyurethane J-tube Seals- urethane J-tube seals are mainly designed for sealing within the J-tube structure. Their purpose is two - fold: to prevent water, debris, or other harmful substances from entering, while allowing cables or other components to pass through.

Advantages of Using Polyurethane Elastomers in Offshore Wind Power Cable Protection

Long Term Cost Effectiveness -Despite the initial investment in polyurethane elastomer products, their long lifespan and low maintenance requirements result in significant cost savings over the life cycle of the offshore wind power project. Reduced cable replacement and repair costs contribute to overall project cost - effectiveness.

Design Flexibility -Polyurethane elastomers can be molded into various shapes and sizes to meet the specific requirements of different cable protection applications. This design flexibility allows for the customization of components to fit the unique geometries and installation needs of offshore wind farms.

Environmental Compatibility-These elastomers are relatively environmentally friendly compared to some traditional cable protection materials. They have a lower environmental impact during production and disposal, aligning with the sustainable nature of the offshore wind power industry.

Pulisen offer reliable and cost-effective polyurethane elastomers products for Offshore Wind Power Cable Protection, and also can constantly developing new urethane products based on your design, thus meeting the needs of offshore wind power cable protection systems.

Explore other Industries Service

Send Inquiry