Urethane Casting

Cast polyurethane products have good flexibility and elasticity, can absorb a certain impact, commonly used in some need to shock absorption, cushioning occasions. Our cast polyurethane services are dedicated to providing you with custom cast urethane products. Hand polyurethane pouring and machine pu pouring gives us the flexibility to meet your production needs for smaller orders.

Whether you need highly wear resistant urethane parts, precision cast urethane parts, or cast urethane products with complex structural designs. With our extensive production experience and diverse urethane molding technologies, we can provide you with one-stop urethane molding solutions. From mold making to pouring to delivery of the finished product, we perform and control every step of the polyurethane casting production process to ensure that the polyurethane cast part is a perfect fit for your application!

Our Urethane Casting Capabilities

We have different flow rate polyurethane elastomer casting machines and comprehensive polyurethane supporting auxiliary equipment, with our many years of production experience and mature polyurethane production process, we can customize your polyurethane products according to your design drawings.- Polyurethane Material Selection

- Mold Design and Fabrication

- Polyurethane Casting - Hand Casting & Machine Casting

- Surface Treatment & CNC Machining Polyurethane Capabilities

Advantages of Polyurethane Casting

Cast polyurethane products has good mechanical strength and excellent resistance to abrasion, oil, chemicals and tearing, as well as good elasticity and impact resistance. Choosing cast urethane molding process to make cast urethane parts has the following advantages:- Suitable for PU parts with complex shapes and large size.

- Custom polyurethane parts based on your design drawing

- Cost-effective for small batch orders with little mold costs

- Urethane can be bonding with steel substrates

Quality Control of Cast Urethane Parts

We strictly control and record parameters such as temperature, pressure, and time during the polyurethane pouring production process to ensure consistent quality of polyurethane products. We are also able to deal with common problems in the poured polyurethane process, such as air bubbles, shrinkage, deformation, etc., to improve the yield rate of the products.

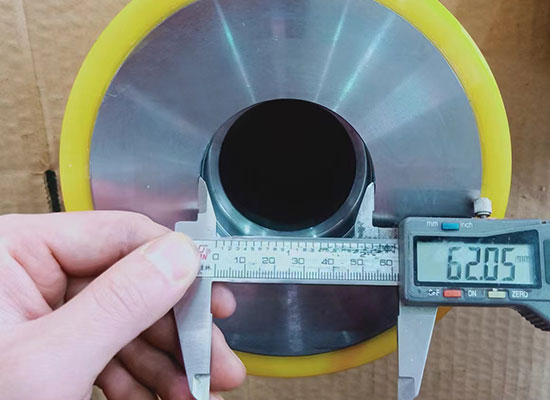

According to your order, we can reasonably arrange the production plan, optimize the production process, improve the production efficiency, and ensure that the products are delivered on time. Meanwhile, we have established a perfect quality inspection system, which can test the appearance, size, hardness, and physical properties of the molded polyurethane products.

Cast Polyurethane Products Examples

Application of Cast Urethane Products

Cast Urethane Manufacturers- You Design it While We Produce It

As a cast polyurethane manufacturer, we can produce cast polyurethane products of various sizes and shapes according to your design drawings.

Our cast urethane services cover all aspects of mold design and manufacturing (with logo inside the mold), polyurethane formulation selection, quality control during the production of cast polyurethane, polyurethane post-processing, finished product inspection, product packaging and shipping arrangements, as well as after-sales technical support and problem solving. We provide one-stop polyurethane solutions for OEM and brand name customers.

Cast Urethane Molding Process

- Mold design and manufacturing

- Polyurethane Material selection and blending

- Poured polyurethane materials into the preheated mold slowly

- Waiting polyurethane cured and then demolding

- Machining polyurethane, such as CNC turning, CNC milling and surface grinding to obtain better appearance and dimensional accuracy.

We don't have a fixed minimum order quantity requirement, but the order quantity will affect the price and delivery time. We will assess and negotiate based on your needs and project details in specific situations.

The delivery time depends on the complexity of the product and the order quantity. Generally, it takes 2 - 6 weeks from placing the order to delivery. However, we will provide you with a more accurate delivery schedule at the beginning of the project.

Yes, we can provide you with samples after determining the specific customization requirements and related costs.

With our professional technical team and advanced production process, we can meet all kinds of complex design and shape requirements and provide you with satisfactory solutions.

The price is mainly calculated according to the material cost of the product, the complexity of the process, the quantity of the order and the customization requirements. We will provide you with a detailed quotation.

If there is any quality problem with the product, we will provide warranty service for a certain period of time and solve the problem for you in time.