Urethane Drive Belt

Urethane Drive Belt is a high-performance belt made from polyurethane, known for its durability, flexibility, and resistance to wear and tear. It is commonly used in machinery and equipment to transmit power efficiently.

Our polyurethane drive belts are made from 100% new and high quality thermoplastic polyurethane elastomer material by polyurethane extrusion molding process. Our poly drive belts offer excellent abrasion resistance and accurate drive performance, providing a reliable and long-lasting power transmission solution for your equipment.

Polyurethane Drive Belt Manufacturer

Characteristics of Urethane Belt Transfer

- Wear Resistance: Surface is resistant to wear, ensuring a long service life.

- High Elasticity: Excellent elasticity suitable for various mechanical transmission systems.

- High Tear and Tensile Strength: Capable of withstanding high tensile and tearing forces.

- Chemical and Oil Resistance: Good resistance to chemicals and oils.

- Low Noise: Operates quietly, suitable for noise-sensitive environments.

- Easy to Connected, Cutted and hot welding to joined as the endless urethane belts as according to your drive wheel distance and pulley size.

Application for Urethane Drive Belts

Polyurethane drive belts widely used in centrifugal fan belt drive, ceramic industry glazing line, polishing line and other conveyor lines, as well as roof tile manufacturing, glass manufacturing, distribution centers, antique sewing machines, bottle conveyor, onion conveyor, canning line and other food processing equipment.

Custom Poly Drive Belts Service

- Product Specifications

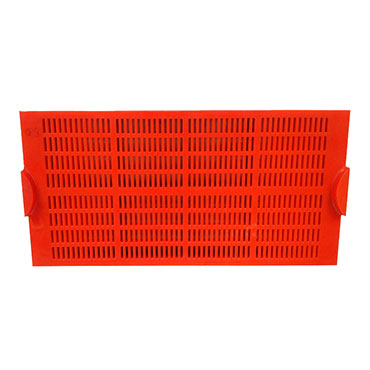

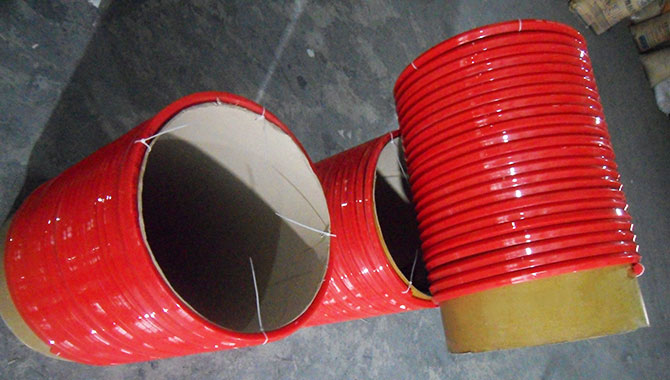

- Gallery

Date sheet of PU V-belts

| PU V-Belts | Non-Reinforced | Also available with Aramid, Steel wire, Kevlar Reinforcement | |||

| Color | Red | White | |||

| Hardness | 90A | 75A | |||

| Temp. Range | -20ºC to +70ºC | -30°C/+50°C | |||

| Cross Section | Dimensions | Length | Minimum Pulley Ø | Pretension | Weight per meter |

| Type | W * H (mm) | Mtrs/Roll | (mm) | Max.6% | (kg) |

| Y | 6*4 | 100 | 40 | 3% | 0.045 |

| M | 8*5 | 100 | 55 | 3% | 0.046 |

| Z/10 | 10*6 | 50 | 65 | 3% | 0.070 |

| A/13 | 13*8 | 30 | 80 | 3% | 0.12 |

| B/17 | 17*11 | 30 | 115 | 3% | 0.197 |

| C/22 | 22*14 | 30 | 145 | 3% | 0.297 |

| D/32 | 32*17.5 | 50 | 215 | 3% | 0.567 |

Date Sheet of PU Super Grip Belts

| Super Grip V-belts | Non-Reinforced | Also available with Aramid, Steel wire, Kevlar Reinforcement | |||

| Color | Red | White | Green | ||

| Hardness | 90A | ||||

| Temp. Range | -30ºC to +55ºC | ||||

| Cross Section | Dimensions | Length | Minimum Pulley Ø | Pretension | Weight per meter |

| Type | W * H (mm) | Mtrs/Roll | (mm) | Max.6% | (kg) |

| A/13 | 13*8 | 30 | 100 | 3% | 0.15 |

| B/17 | 17*11 | 30 | 150 | 3% | 0.22 |

| C/22 | 22*14 | 30 | 210 | 3% | 0.384 |

Date Sheet of PU Ridge Top V Belts(Pentagonal or Heptagonal Belts)

| Ridge Top V-belts | Non-Reinforced | available with Aramid, Steel wire, Kevlar Reinforcement | |||

| Color | Red | White | |||

| Hardness | 90A | ||||

| Temp. Range | -20ºC to +70ºC | ||||

| Cross Section | Dimensions | Length | Minimum Pulley Ø | Pretension | Weight per meter |

| Type | W * H (mm) | Mtrs/Roll | (mm) | Max.6% | (kg) |

| A/13 | 13*15 | 30 | 140 | 3% | 0.15 |

| B/17 | 17*19 | 30 | 200 | 3% | 0.22 |

| C/22 | 22*24.5 | 30 | 240 | 3% | 0.384 |

Date Sheet of PU Hexagon Belts (Double-V belts)

| Hexagon belts | Non-Reinforced | available with Aramid, Steel wire, Kevlar Reinforcement | |||

| Color | Red | White | |||

| Hardness | 90A | ||||

| Temp. Range | -20ºC to +70ºC | ||||

| Cross Section | Dimensions | Length | Minimum Pulley Ø | Pretension | Weight per meter |

| Type | W * H (mm) | Mtrs/Roll | (mm) | Max.6% | (kg) |

| AA | 13*10 | 30 | 105 | 3% | 0.15 |

| BB | 17*13 | 30 | 143 | 3% | 0.22 |

| CC | 22*17 | 30 | 216 | 3% | 0.384 |

Date Sheet of Twin V-belts

| Twin / double v-belts | Non-Reinforced | Accept custom according to sample or drawing | |||

| Color | Red | Orange | Blue | White | |

| Hardness | 85A | ||||

| Temp. Range | -40ºC to +55ºC | ||||

| Cross Section | Dimensions | Length | Minimum Pulley Ø | Pretension | Fax/belt (standard) |

| Type | W * H (mm) | Mtrs/Roll | (mm) | Max.6% | (kg) |

| M | 21*8 | 30 | 80 | 3% | 28 |

| Z | 24*6.8 | 30 | 60 | 3% | 28 |

| A | 30*8 | 30 | 80 | 3% | 45 |

Related Products

What is polyurethane drive belts application scenario?

1. Industrial Machinery

- 1) Conveying Systems: Polyurethane belts are commonly employed in conveyor systems for transporting goods and materials in manufacturing facilities, distribution centers, airports, and other logistics operations. They provide reliable and efficient conveying while withstanding heavy loads and harsh operating conditions.

- 2) Power Transmission: Polyurethane belts are often used for power transmission applications in various industries such as manufacturing, automotive, and agriculture. They can efficiently transfer power from one rotating shaft to another, even over long distances.

- 3)Textile Machinery: The textile industry relies on polyurethane drive belts in spinning, weaving, and knitting machines. These belts need to be flexible enough to accommodate the complex movements of the machinery while also providing consistent power transfer. They help ensure the smooth operation of the equipment, resulting in high-quality textile products.

- 4)Woodworking: Polyurethane belts are employed in woodworking machinery for tasks such as cutting, sanding, and shaping wood. They provide a strong grip on workpieces, ensuring precise and efficient processing.

- 5)Fitness Equipment: Polyurethane belts are used in gym equipment such as treadmills, exercise bikes, and weight machines. They provide smooth and quiet operation, along with durability to withstand continuous use in fitness environments.

2. Automotive Industry

- 1) Engine Accessories: Polyurethane drive belts are used to drive engine accessories such as the alternator, water pump, power steering pump, and air conditioning compressor. They are designed to withstand the high temperatures and mechanical stresses present in the engine compartment. Their durability and reliability are essential for the proper functioning of these accessories and the overall performance of the vehicle.

- 2) Polyurethane belts are found in automotive engines as timing belts or accessory drive belts. They transmit power from the crankshaft to various engine components such as the camshaft, water pump, and alternator, contributing to efficient engine operation.

3. Office Equipment

- 1) Printers and Copiers: In printers and copiers, polyurethane drive belts are used to move the paper through the machine and to drive the various rollers and components. They need to be quiet in operation and provide smooth, consistent movement to ensure high-quality printing and copying. Their flexibility allows them to fit into the compact design of office equipment.

- 2) Fax Machines and Scanners: Similar to printers and copiers, fax machines and scanners use polyurethane drive belts to transport documents and operate the scanning and transmission mechanisms. These belts help ensure the accurate and efficient operation of these devices.

4. Food and Beverage Industry

- 1) Food Processing Equipment: Polyurethane drive belts are commonly used in food processing machinery such as conveyors, mixers, and packaging equipment. They are made from food-grade materials that are safe for contact with food products. Their resistance to moisture, chemicals, and bacteria makes them suitable for the hygienic requirements of the food industry.

- 2) Beverage Bottling Lines: In beverage bottling plants, polyurethane drive belts are used to move bottles along the production line, from filling to capping and labeling. They need to be able to handle the weight and shape of the bottles while maintaining a high level of hygiene.

Urethane drive belts is elastic and has excellent wear resistance. They are also resistant to oils, chemicals, and can last longer than traditional rubber belts.

Yes, we can provide you small samples for testing and evaluation to ensure that it meets your needs, if we have it in stock, but consider for international freight cost, we suggest to place sample order to check the quality.

The MOQ depends on the specification and complexity of the product. Generally, the MOQ is 300-500 meter, please contact our sales team for details.

Generally, 12-15 working days from the confirmation of order and molds design. However, the exact time may vary depending on the quality of the order.

Yes, we provide food-grade urethane drive belts that meet industry standards for safety and hygiene, making them suitable for food processing and packaging applications.